Table of Contents

- Introduction

- Why UV Laser Marking Machines Are Ideal for Plastics

- Key Applications of UV Laser Marking Machines in the Plastic Industry

- Product Labeling and Branding

- Traceability and Serial Number Marking

- Medical Equipment and Devices

- Automotive and Aerospace Components

- Electronics and Consumer Goods

- Advantages of Using UV Laser Marking Machines for Plastics

- Conclusion

Introduction

Top Applications of UV Laser Marking Machines in the Plastic Industry

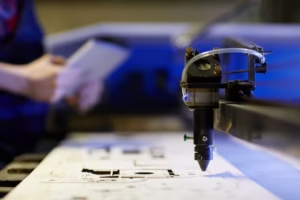

UV Laser Marking Machines have revolutionized the plastic industry by providing high-precision, permanent, and non-contact marking solutions. These machines use ultraviolet laser beams to create fine markings without damaging the material, making them an ideal choice for delicate plastic products. In this blog, we will explore the top applications of UV Laser Marking Machines in the plastic industry and how they enhance efficiency and product quality.

Why UV Laser Marking Machines Are Ideal for Plastics

Plastics are widely used across industries, and ensuring proper identification, branding, and traceability is essential. UV Laser Marking Machines stand out due to their ability to mark plastics without causing thermal damage. The cold marking process ensures clear, high-contrast markings while maintaining the integrity of the material. Additionally, these machines work with a variety of plastic types, including ABS, PVC, polycarbonate, and acrylic.

Key Applications of UV Laser Marking Machines in the Plastic Industry

1. Product Labeling and Branding

One of the most common uses of Laser Marking Machines in the plastic industry is for product labeling and branding. Manufacturers can etch company logos, product names, and certification marks directly onto plastic surfaces, ensuring durability and resistance to wear and tear. Unlike traditional ink-based printing, laser marking provides a permanent solution that does not fade over time.

2. Traceability and Serial Number Marking

With increasing regulations and quality control requirements, traceability has become a critical aspect of plastic manufacturing. Laser Marking Machines enable the engraving of serial numbers, QR codes, and barcodes on plastic parts, ensuring seamless tracking throughout the supply chain. This helps manufacturers maintain compliance and improve operational efficiency.

3. Medical Equipment and Devices

The medical industry relies on plastic components for various equipment, such as syringes, surgical tools, and IV bags. UV Laser Marking Machines allow for precise, non-toxic, and contamination-free markings, ensuring compliance with stringent medical standards. The high contrast and accuracy of laser-marked labels aid in easy identification and usage of medical instruments.

4. Automotive and Aerospace Components

In the automotive and aerospace industries, plastic parts require permanent markings for identification, part numbering, and safety compliance. Laser Marking Machines are used to engrave warning labels, component details, and safety instructions onto dashboard panels, wiring insulation, and other plastic components. This helps improve traceability and ensures adherence to industry standards.

5. Electronics and Consumer Goods

From mobile phone casings to household appliances, electronics and consumer goods frequently utilize Laser Marking Machines for branding and identification. Marking serial numbers, certification marks, and technical specifications directly onto plastic parts enhances product aesthetics while ensuring authenticity and traceability. The ability to produce fine, high-resolution markings makes laser marking the preferred choice for electronic manufacturers.

Advantages of Using UV Laser Marking Machines for Plastics

- High Precision: Delivers fine, detailed markings without damaging plastic surfaces.

- Non-Contact Process: Ensures wear-free marking with minimal maintenance.

- Permanent and Durable: Resistant to fading, scratching, and chemical exposure.

- Eco-Friendly: No ink, chemicals, or consumables required.

- Versatile: Compatible with various plastic types and applications.

Conclusion

UV Laser Marking Machines have become an essential tool in the plastic industry, offering unmatched precision, durability, and efficiency. From product labeling to medical devices and automotive components, their applications are vast and impactful. As industries continue to evolve, the demand for reliable and eco-friendly marking solutions like Laser Marking Machines will only grow. Investing in these advanced systems ensures superior product quality, compliance, and long-term cost savings.